Metal vs. Wooden Bunk Beds

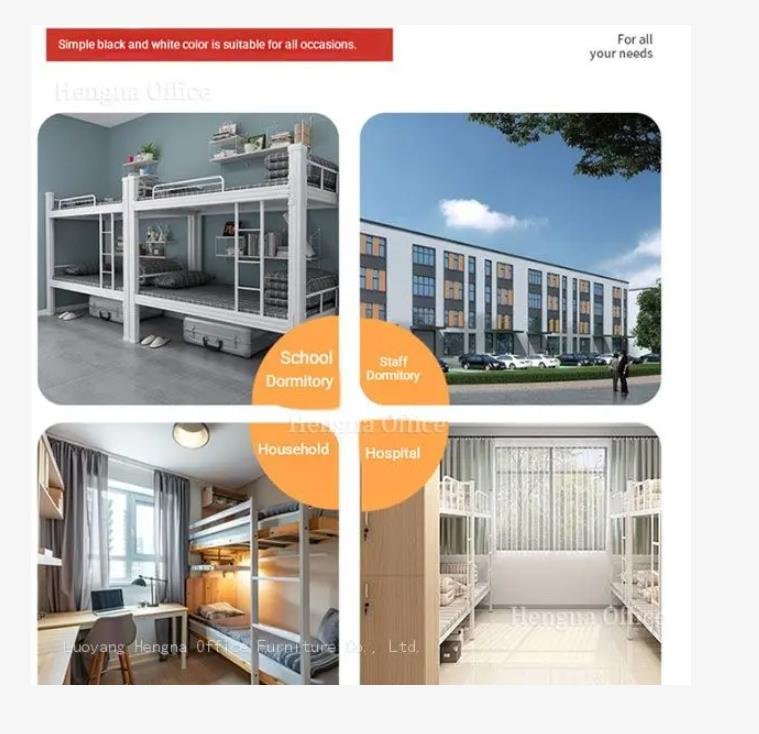

Heavy Duty Metal Bunk Bed vs. Wooden Bunk Beds .When selecting bunk beds for commercial spaces like dormitories, labor camps, and hotels, durability, safety, and long-term cost are key considerations. While wooden bunk beds are favored in residential settings for their natural grain and cozy ambiance, the high-frequency use, humid environments, and shared occupancy demands of commercial settings make heavy-duty metal bunk beds the superior choice. This article compares key dimensions to help you identify the most suitable option for commercial settings.

1. Wooden Beds: The “Cozy Choice” for Homes, but “Shortcomings” for Commercial Settings

Wooden bunk beds excel in natural aesthetics and warmth, making them ideal for low-frequency residential use. However, commercial spaces (like labor camps or dormitories) face challenges including:

- Frequent climbing (multiple daily uses);

- Humid environments (near shower areas or in rainy regions);

- Multiple occupants (high weight-bearing demands).

Wooden beds’ weaknesses include:

- Susceptibility to moisture expansion, insect damage, and frame loosening over time;

- Limited weight capacity posing safety risks for adults;

- High maintenance costs (requiring regular waxing, pest control, and frequent part replacements).

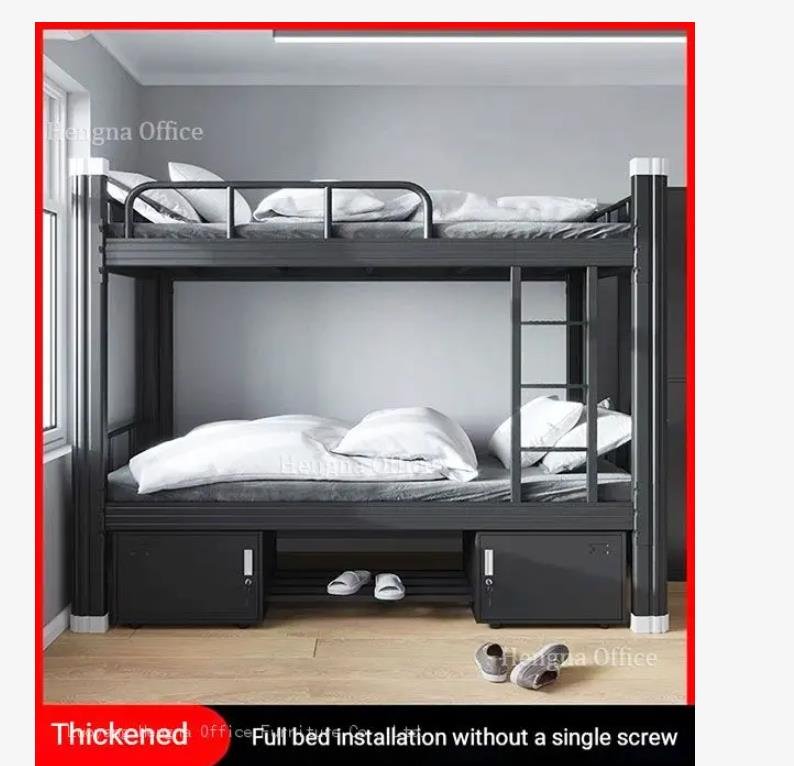

2. Heavy Duty Metal Bunk Bed : The “Durability Champion” for Commercial Settings, with Comprehensive Advantages

Heavy-duty metal bunk beds are specifically engineered for commercial environments. Through optimized materials, craftsmanship, and construction, they overcome the limitations of wooden beds, making them the preferred choice for commercial use.

(1) Durability: Steel construction withstands rigorous use, passing 300-hour salt spray testing

Commercial spaces demand high stability from bed frames due to frequent use and humid conditions. Metal beds feature:

- Cold-rolled steel profiles: Bed posts 70×70mm (wall thickness 1.1mm), crossbeams 83×30mm (thickness 0.9mm), with dual-sided epoxy plastic coating;

- Upgraded manufacturing: CO₂ shielded welding + multi-step coating (degreasing, rust removal, acid washing, surface conditioning, ceramic conversion, electrostatic powder coating), 300-hour salt spray testing, delivering corrosion and deformation resistance far exceeding wooden beds.

Even in prolonged humid conditions, no rot or loosening occurs, ensuring a service life exceeding 10 years.

(2) Safety: Detailed Design Eliminates Hazards

In commercial settings, safety is non-negotiable. Metal beds ensure safety through these designs:

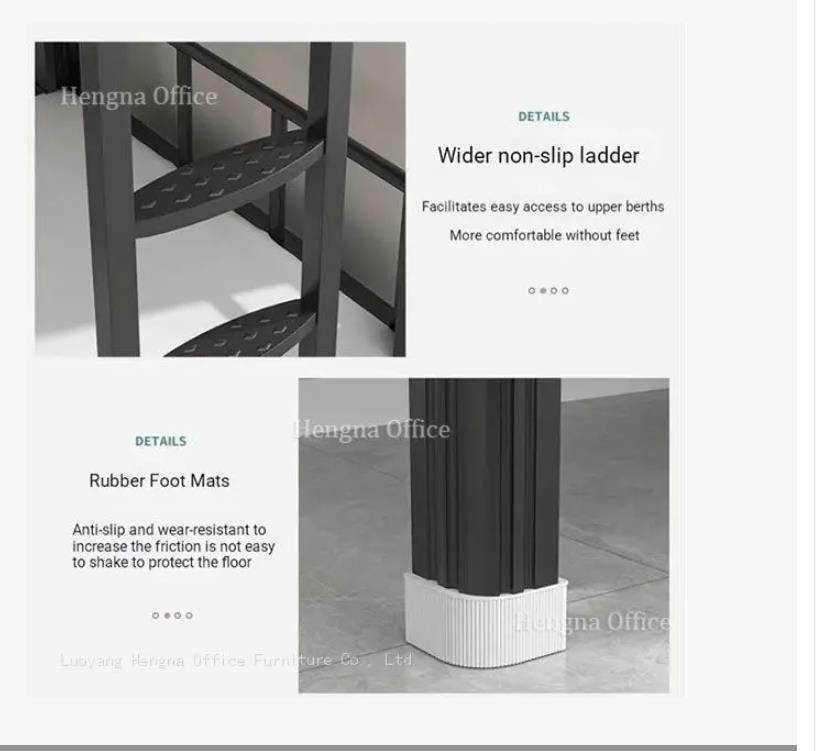

- Guardrails: 19mm diameter × 1.0mm thick premium round steel tubing, connected to the headboard crossbeam in a “cross” configuration. Height: 255mm, effectively preventing falls;

- Bed ladder: 20mm × 30mm rectangular tubing, 1.0mm thick. Steps: 246mm × 55mm × 1.2mm, double-sided curved one-piece stamping with anti-slip ridges to prevent slipping;

- Connection method: Three-hole dowel-locking system (no bolts). Bed posts and crossbars integrate tightly for stable load-bearing (suitable for adults), remaining secure even with frequent use.

(3) Maintenance Costs: Metal Beds “Worry-Free,” Wooden Beds “Costly”

In commercial operations, maintenance costs directly impact profitability. Metal beds offer distinct advantages:

- Smooth surfaces facilitate easy wiping and strong stain resistance;

- Coatings withstand wear without frequent repainting or part replacement, resulting in long-term maintenance costs only one-third that of wooden beds.

Wooden beds require periodic waxing, pest prevention, and drying if damp—complex maintenance processes with high costs.

(4) Environmental Sustainability: Metal Beds Are Recyclable; Wooden Beds Depend on Source

As sustainability awareness grows, environmental impact has become a key consideration in commercial procurement. Metal beds:

- Steel is recyclable, and coatings use eco-friendly epoxy resin, meeting green building standards;

- Wooden beds may pose environmental risks if sourced from illegal logging or unsustainable forests. Even from sustainable sources, processing can generate higher carbon emissions.

(5) Ease of Assembly/Disassembly: Metal Beds Are More Efficient

In commercial settings, assembly/disassembly efficiency is critical during bulk installations or relocations. Metal beds use a three-hole dowel-and-slot connection, enabling tool-free rapid assembly—ideal for quick-deployment scenarios like labor camps or dormitories. Wooden beds typically require tools like screwdrivers, leading to time-consuming installation and potential loosening after repeated assembly/disassembly.

3. Conclusion: Heavy-Duty Metal Bunk Beds Are the Preferred Choice for Commercial Settings

For commercial spaces requiring high-frequency use, long-term durability, and low maintenance costs (e.g., labor camps, dormitories, hotels), heavy-duty metal bunk beds are the superior option. Their rugged construction, safety features, and ease of maintenance significantly reduce operational costs while enhancing user experience.