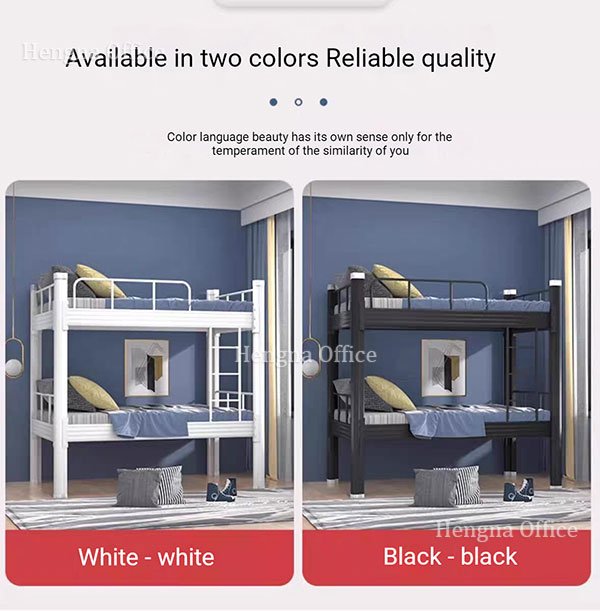

Heavy Duty Black Metal Bunk Bed for Adults

In factory dormitories, construction camps, seasonal worker housing, and budget hotels, beds are more than just furniture—they are durable assets enduring daily heavy use. These environments demand solutions that withstand frequent use over extended periods, meet adult weight requirements, and minimize maintenance costs. Standard home bunk beds or flimsy steel frame beds often develop wobbling, squeaking, or structural issues within months. Our Heavy-Duty Black Metal Adult Bunk Bed is engineered to meet these demanding challenges. It combines industrial-grade structural strength, comprehensive safety features, and user-friendly, simple assembly—crafted for group accommodation managers seeking long-term value and reliability.

Constructed entirely of steel with a sleek black electrostatic powder-coated finish, this bed is not only exceptionally durable but also seamlessly complements modern or industrial-style lodging environments. Its core design philosophy centers on: achieving ultimate stability through boltless, snap-fit connections; ensuring user safety with integrated guardrails and fixed ladders; and enabling rapid deployment via pre-assembled components and clear instructions, significantly reducing installation time and labor costs. Whether outfitting a new workshop dormitory or updating existing lodging facilities, this bed delivers enduring, reliable performance.

I. Rock-Solid: Engineered Heavy Duty Black Metal Bunk Bed for Durability

The bed’s robustness begins with its materials and connection technology, ensuring quiet and stable operation for years.

Heavy-Duty Cold-Rolled Steel Frame: The main framework (uprights and crossbars) is constructed from high-quality cold-rolled steel. Uprights feature 70mm x 70mm large-section extruded profiles with 1.1mm wall thickness; crossbars utilize 83mm x 30mm extruded structures with 0.9mm wall thickness. This use of thickened materials provides far superior bending resistance and deformation resistance compared to ordinary square tube beds, ensuring the entire structure remains stable without sagging or shaking, even during frequent activity on the upper bunk.

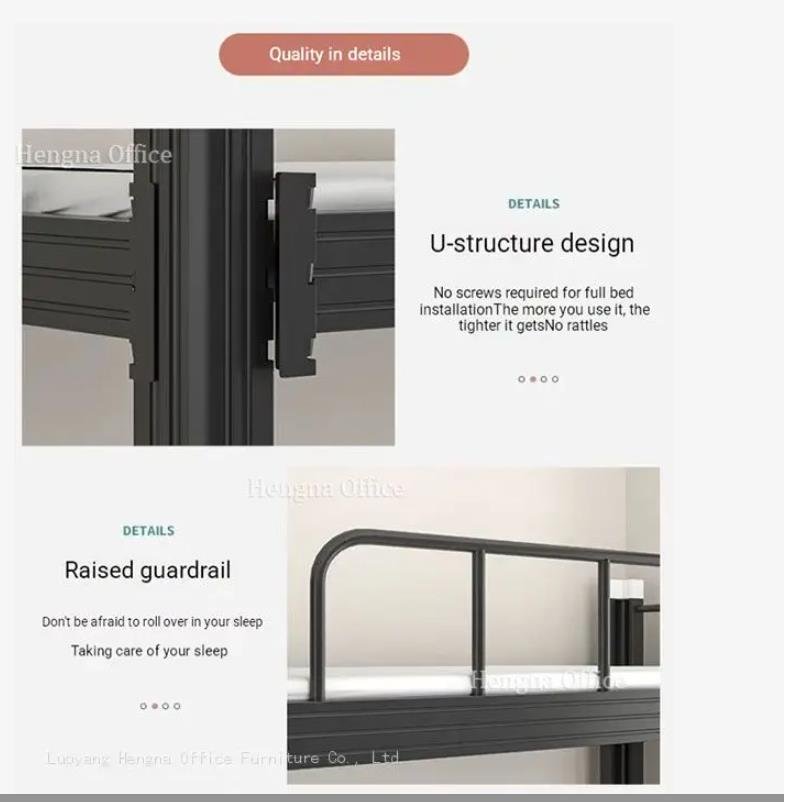

Revolutionary Three-Hole Tenon-and-Slot Connection System: This is the core advantage that distinguishes this product from traditional bolted beds. All connections between vertical posts and crossbeams are achieved through precision three-hole tenons and grooves that interlock directly, completely eliminating the need for bolts or screws. This design delivers two fundamental benefits:

- Ultimate Stability: The physical interlocking of metal components ensures even force distribution under load, fundamentally eliminating chronic bed swaying and squeaking noises caused by bolt loosening.

- Rapid Assembly: The assembly process requires no tightening of dozens of screws, significantly reducing installation time and labor intensity.

II. Comprehensive Protection: User sturdy black bunk bed with ladder in Design

Safety is the foremost responsibility in collective accommodation management. We build a secure resting environment for users through multiple design details.

High-Strength Integrated Headboard Guardrail: The guardrail is not an aftermarket accessory but is firmly welded to the headboard crossbeam using CO₂ shielded arc welding, forming a robust “square” structure. Constructed from high-quality solid round steel tubing (Φ19mm x 1.0mm), it stands at 255mm in height. This safety-compliant height effectively prevents falls during sleep, while its welded strength withstands accidental impacts.

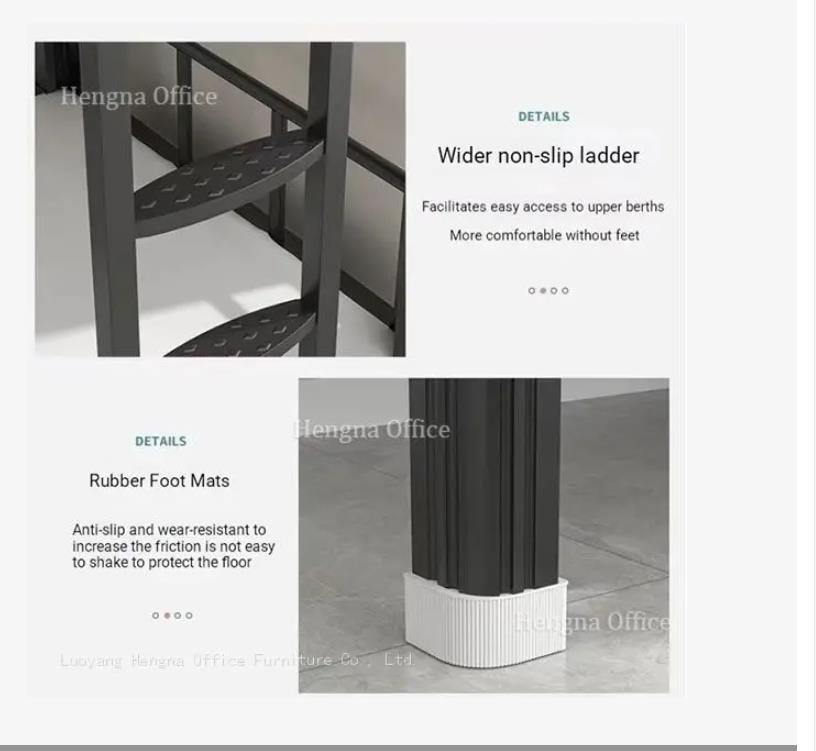

Non-slip, Secure Fixed Ladder: The ladder is an integral part of the bed frame. The ladder frame is welded from 20mm x 30mm thick-walled rectangular tubing. The steps feature a wide, single-stamped design (246mm x 55mm, 1.2mm thick) with raised anti-slip grooves. Steps are firmly welded to the ladder frame, eliminating wobbling or rattling, ensuring safe and convenient access between bunk levels.

Comprehensive Collision Protection: All exposed metal tube ends—including column tops, beam ends, and guardrail vertical tube tops—feature 3mm-thick ABS engineering plastic caps. These caps effectively prevent accidental bumps and injuries while protecting walls and personal belongings from scratches caused by sharp metal edges.

III. Simplified Deployment: Saving Time and Costs for Administrators

We understand that installation efficiency is paramount for administrators handling bulk purchases.

Modular Pre-Assembled Design: Major bed frame components—such as headboards with guardrails, footboards, and side rails—are fully welded before leaving the factory. On-site assembly essentially involves a “plug-and-lock” process, significantly streamlining steps.

Sturdy Out-of-the-Box: Once assembled, the bed forms a solid, integrated structure—eliminating the need for repeated tightening required by bolted beds. You can immediately lay the bed slats (recommended: 14mm+ solid plywood) and mattress for immediate use.

IV. Traditional Bolted Beds vs. Our Heavy-Duty Plug-in Beds: A Manager’s Perspective Comparison

| Consideration | Traditional Bolted Bunk Beds | Our Heavy-Duty Plug-in Bunk Beds |

|---|---|---|

| Long-Term Stability | Bolts can loosen due to usage vibrations, requiring regular inspection and retightening to prevent shaking and noise. | Three-hole tenon-slot connections form a rigid structure with zero loosening potential, maintaining initial stability long-term with minimal maintenance. |

| Installation Efficiency | Requires aligning holes individually and tightening numerous bolts, consuming significant time and demanding high physical effort from installers. | Modular pre-assembled components enable rapid “plug-and-lock” assembly, drastically reducing installation time and labor intensity. |

| Corrosion Resistance | Damaged coatings around bolt holes become corrosion entry points, compromising aesthetics and strength. | Bolt-free design preserves surface coating integrity. Combined with double-sided powder coating, rust resistance is comprehensively enhanced. |

| Total Cost of Ownership | Initial purchase price may be slightly lower, but maintenance costs (tightening/replacing rusted bolts) and potential repair costs from loosening are higher. | The initial investment delivers excellent value, with extremely low ongoing maintenance costs and extended service life resulting in a lower total cost of ownership. |

Its unmatched stability, comprehensive safety design, and efficient assembly experience provide lasting peace of mind and convenience. We welcome bulk purchase inquiries and offer customized configuration services (such as size adjustments) to meet your specific project requirements.